Choose your country

We work in partnership with many official Kymco dealers around the world.

You can select the country of your choice from the list below, whatever your choice, we can deliver worldwide!

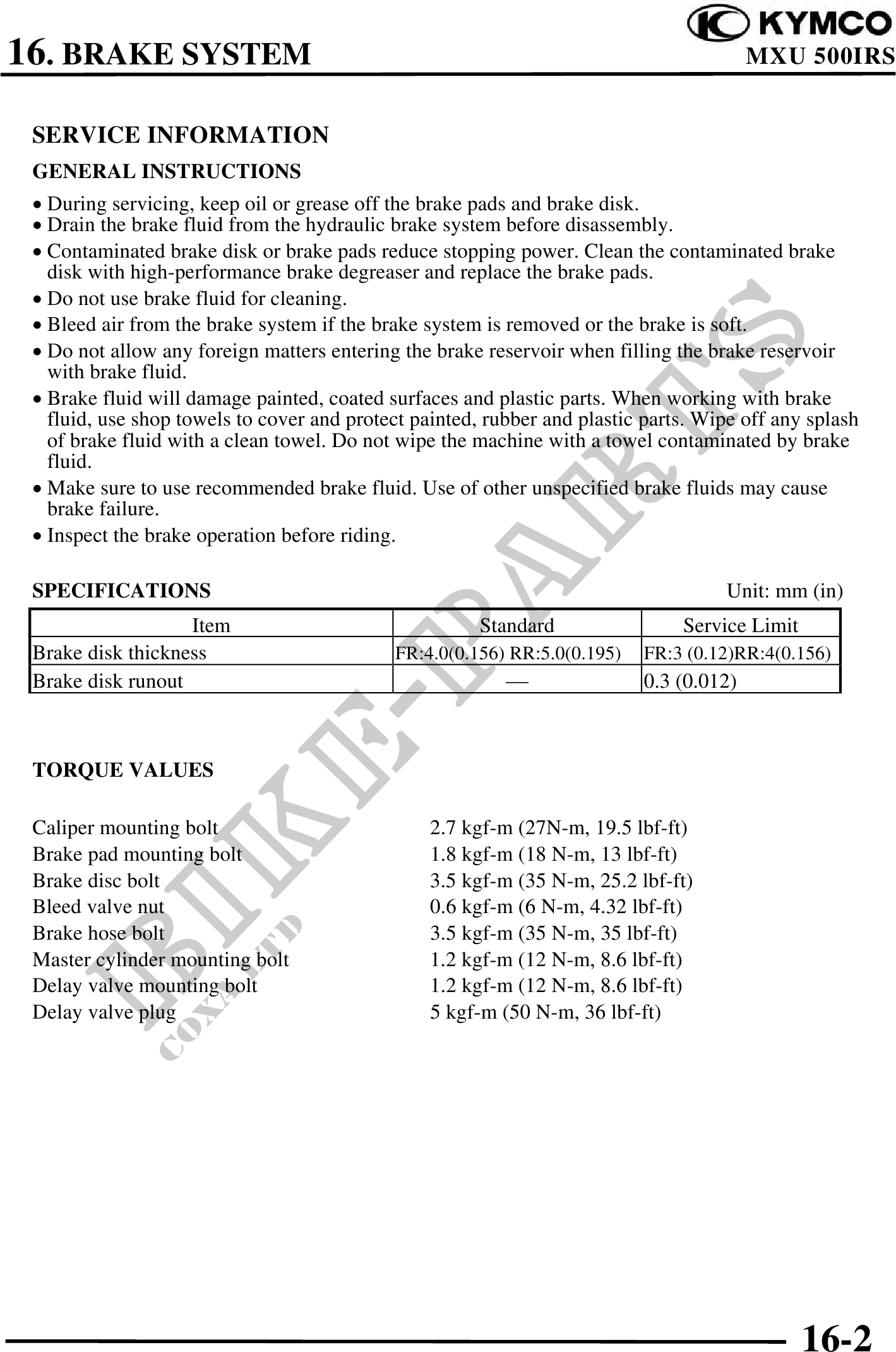

16. BRAKE SYSTEM MXU 500IRS

SERVICE INFORMATION

GENERAL INSTRUCTIONS

· During servicing, keep oil or grease off the brake pads and brake disk.

· Drain the brake fluid from the hydraulic brake system before disassembly.

· Contaminated brake disk or brake pads reduce stopping power. Clean the contaminated brake

disk with high-performance brake degreaser and replace the brake pads.

· Do not use brake fluid for cleaning.

· Bleed air from the brake system if the brake system is removed or the brake is soft.

· Do not allow any foreign matters entering the brake reservoir when filling the brake reservoir

with brake fluid.

· Brake fluid will damage painted, coated surfaces and plastic parts. When working with brake

fluid, use shop towels to cover and protect painted, rubber and plastic parts. Wipe off any splash

of brake fluid with a clean towel. Do not wipe the machine with a towel contaminated by brake

fluid.

· Make sure to use recommended brake fluid. Use of other unspecified brake fluids may cause

brake failure.

· Inspect the brake operation before riding.

SPECIFICATIONS Unit: mm (in)

Item Standard Service Limit

Brake disk thickness FR:4.0(0.156) RR:5.0(0.195) FR:3 (0.12)RR:4(0.156)

Brake disk runout 0.3 (0.012)

TORQUE VALUES

Caliper mounting bolt 2.7 kgf-m (27N-m, 19.5 lbf-ft)

Brake pad mounting bolt 1.8 kgf-m (18 N-m, 13 lbf-ft)

Brake disc bolt 3.5 kgf-m (35 N-m, 25.2 lbf-ft)

Bleed valve nut 0.6 kgf-m (6 N-m, 4.32 lbf-ft)

Brake hose bolt 3.5 kgf-m (35 N-m, 35 lbf-ft)

Master cylinder mounting bolt 1.2 kgf-m (12 N-m, 8.6 lbf-ft)

Delay valve mounting bolt 1.2 kgf-m (12 N-m, 8.6 lbf-ft)

Delay valve plug 5 kgf-m (50 N-m, 36 lbf-ft)

16-2