Choose your country

We work in partnership with many official Kymco dealers around the world.

You can select the country of your choice from the list below, whatever your choice, we can deliver worldwide!

10.FINAL REDUCTION/

TRANSMISSION SYSTEM MXU 300/250

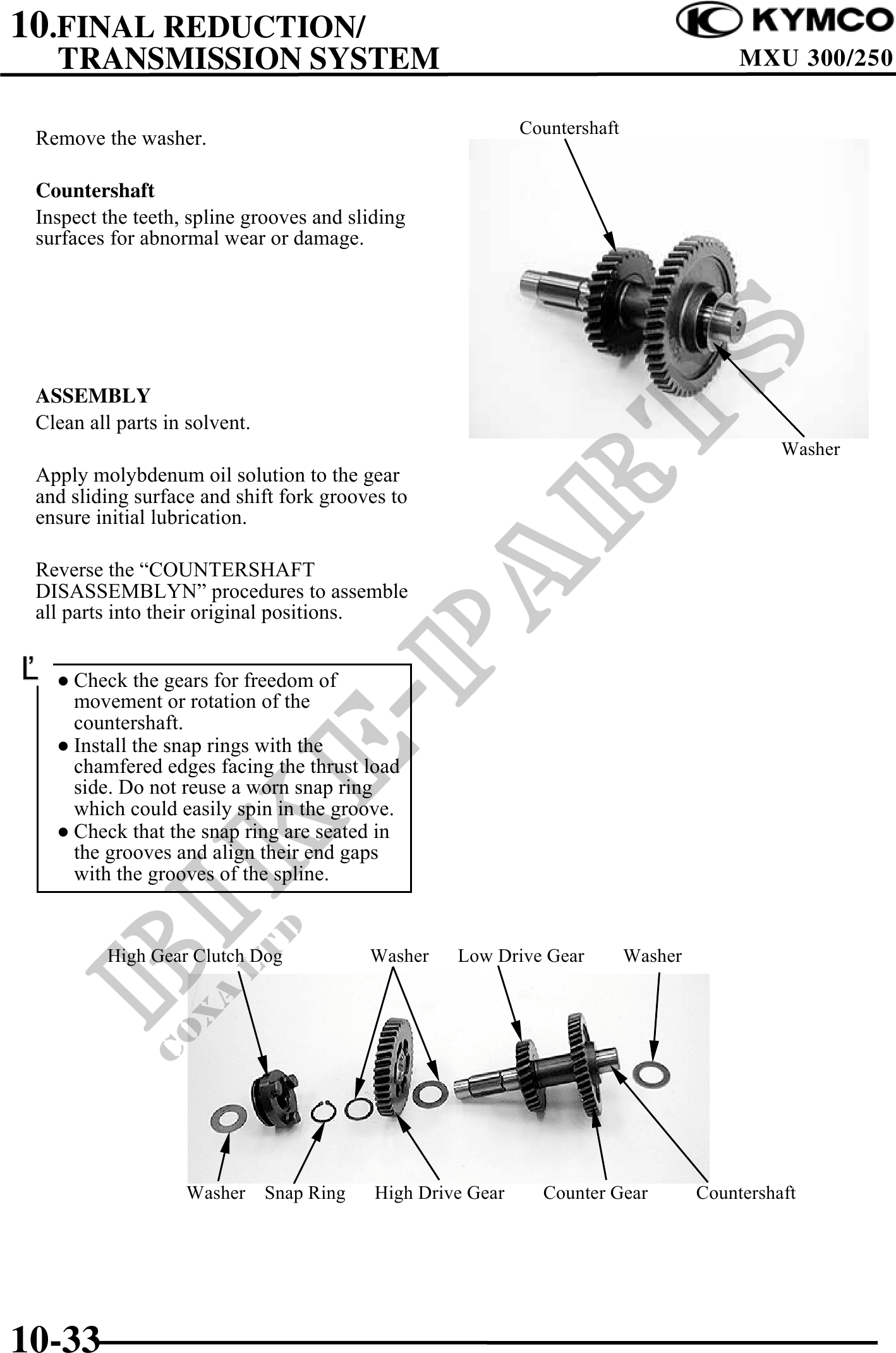

Countershaft

Remove the washer.

Countershaft

Inspect the teeth, spline grooves and sliding

surfaces for abnormal wear or damage.

ASSEMBLY

Clean all parts in solvent.

Washer

Apply molybdenum oil solution to the gear

and sliding surface and shift fork grooves to

ensure initial lubrication.

Reverse the "COUNTERSHAFT

DISASSEMBLYN" procedures to assemble

all parts into their original positions.

Check the gears for freedom of

movement or rotation of the

countershaft.

Install the snap rings with the

chamfered edges facing the thrust load

side. Do not reuse a worn snap ring

which could easily spin in the groove.

Check that the snap ring are seated in

the grooves and align their end gaps

with the grooves of the spline.

High Gear Clutch Dog Washer Low Drive Gear Washer

Washer Snap Ring High Drive Gear Counter Gear Countershaft

10-33