Choose your country

We work in partnership with many official Kymco dealers around the world.

You can select the country of your choice from the list below, whatever your choice, we can deliver worldwide!

15. REAR WHEEL/AXLE/SUSPENSION

DRIVING MECHANISM MXU 300/250

Remove he oil cap.

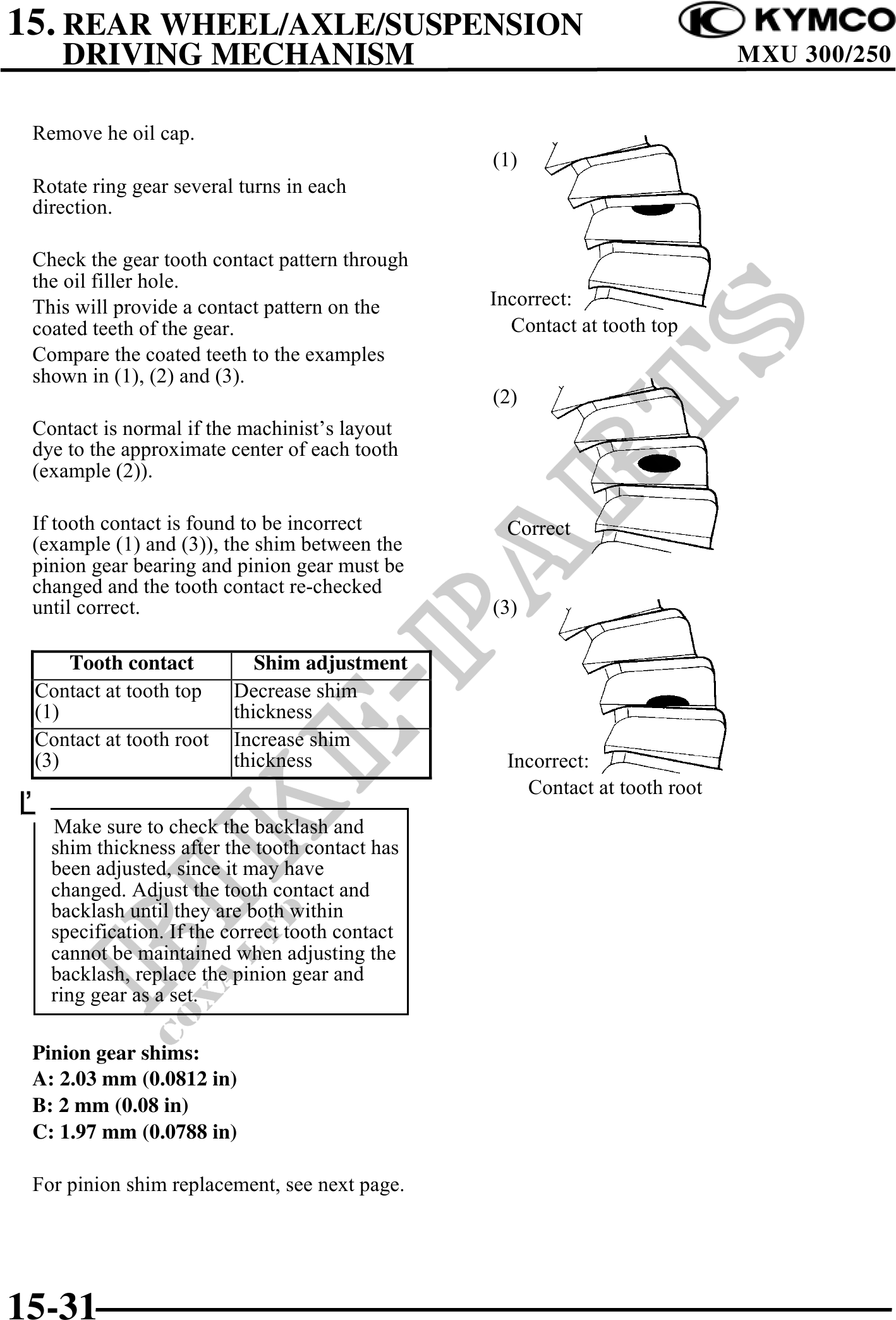

(1)

Rotate ring gear several turns in each

direction.

Check the gear tooth contact pattern through

the oil filler hole.

This will provide a contact pattern on the Incorrect:

coated teeth of the gear. Contact at tooth top

Compare the coated teeth to the examples

shown in (1), (2) and (3).

(2)

Contact is normal if the machinist's layout

dye to the approximate center of each tooth

(example (2)).

If tooth contact is found to be incorrect Correct

(example (1) and (3)), the shim between the

pinion gear bearing and pinion gear must be

changed and the tooth contact re-checked

until correct. (3)

Tooth contact Shim adjustment

Contact at tooth top Decrease shim

(1) thickness

Contact at tooth root Increase shim

(3) thickness Incorrect:

Contact at tooth root

Make sure to check the backlash and

shim thickness after the tooth contact has

been adjusted, since it may have

changed. Adjust the tooth contact and

backlash until they are both within

specification. If the correct tooth contact

cannot be maintained when adjusting the

backlash, replace the pinion gear and

ring gear as a set.

Pinion gear shims:

A: 2.03 mm (0.0812 in)

B: 2 mm (0.08 in)

C: 1.97 mm (0.0788 in)

For pinion shim replacement, see next page.

15-31