Choose your country

We work in partnership with many official Kymco dealers around the world.

You can select the country of your choice from the list below, whatever your choice, we can deliver worldwide!

1. GENERAL INFORMATION DINK 50/125

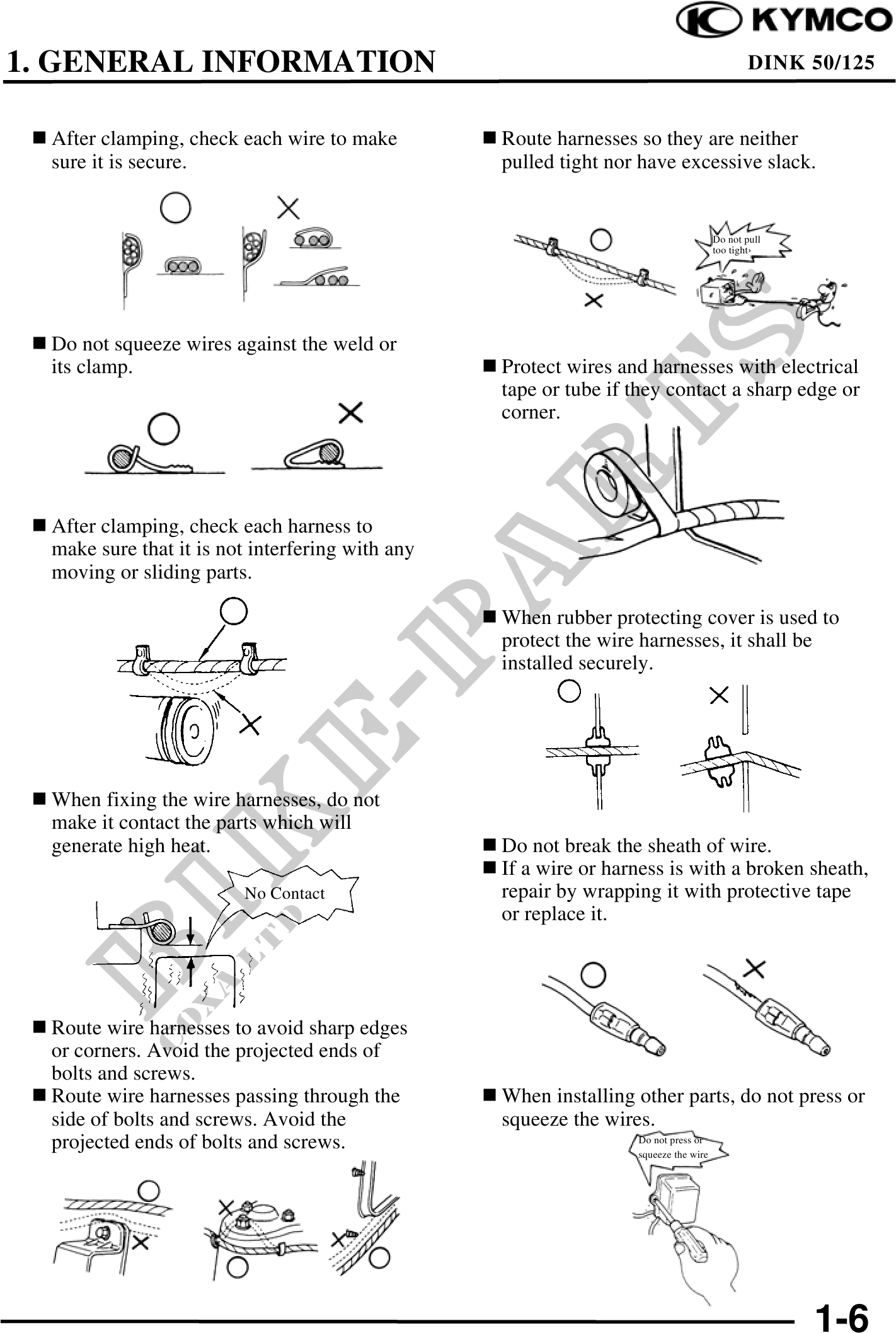

After clamping, check each wire to make Route harnesses so they are neither

sure it is secure. pulled tight nor have excessive slack.

Do not pull

too tight

Do not squeeze wires against the weld or

its clamp. Protect wires and harnesses with electrical

tape or tube if they contact a sharp edge or

corner.

After clamping, check each harness to

make sure that it is not interfering with any

moving or sliding parts.

When rubber protecting cover is used to

protect the wire harnesses, it shall be

installed securely.

When fixing the wire harnesses, do not

make it contact the parts which will

generate high heat. Do not break the sheath of wire.

If a wire or harness is with a broken sheath,

No Contact repair by wrapping it with protective tape

or replace it.

Route wire harnesses to avoid sharp edges

or corners. Avoid the projected ends of

bolts and screws.

Route wire harnesses passing through the When installing other parts, do not press or

side of bolts and screws. Avoid the squeeze the wires.

projected ends of bolts and screws. Do not press or

squeeze the wire

1-6